Customer-focused steel solutions that are essential in the 21st Century.

Customer-focused steel solutions that are essential in the 21st Century.

Our Beginnings

Evonith Steel is Nithia Capital’s foray into the metals & mining industry in India. It will be the umbrella brand as Nithia continues to expand its ventures in the industry, to build synergies and offer a wide range of metal and mining products, including but not limited to high-quality steel products.

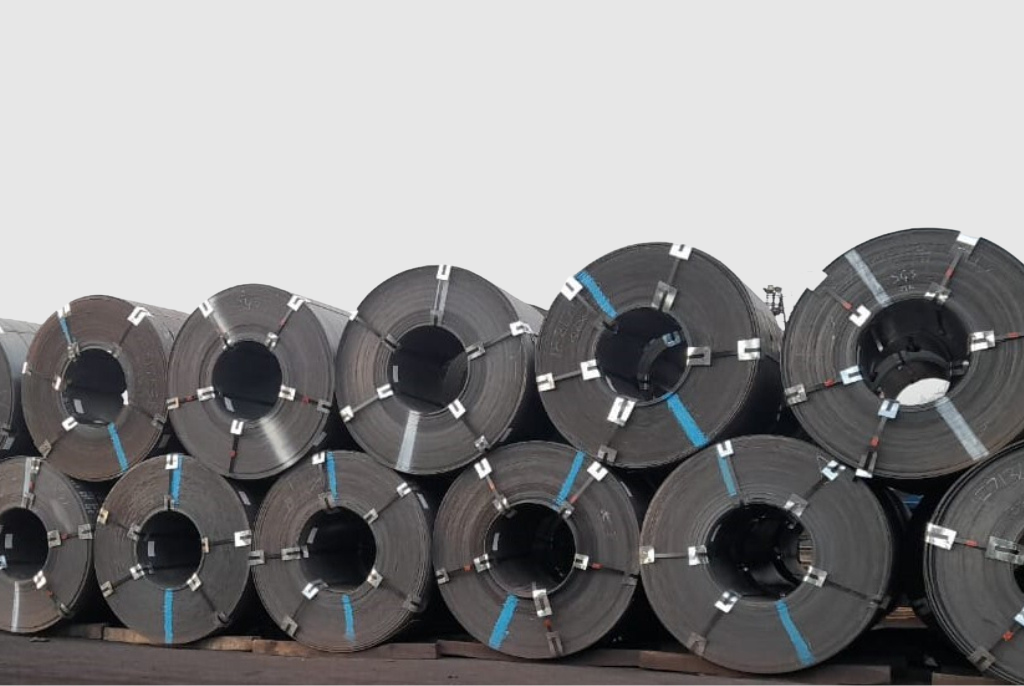

Evonith Steel is the evolution of the steelmaking facilities located at the Wardha Steel Complex, in the state of Maharashtra. The facilities at Wardha Steel Complex are made up of Evonith Metallics Limited (“EML”), formerly known as Uttam Galva Metallics Limited (“UGML”) and Evonith Value Steel Limited (“EVSL”) formerly known as Uttam Value Steels Limited (“UVSL”). Evonith Steel is a leading flat-steel manufacturer based in Wardha, Maharashtra with an impressive 1 MTPA of crude steel output. Strategically located close to India’s geographical centre, Evonith’s Wardha Steel Complex enjoys superior transport services and access to vital resources as well as its own five-platform railway siding for logistical ease. Evonith Steel has been proudly serving MSMEs and OEMs with quality steel and mining products since 1994 and is now aiming higher still, to become one of India’s foremost steel producers.

Evonith Steel is known to offer cost-effective products and services that fit the raw material needs of various industry verticals, including but not limited to railways and other government organizations. Thanks to the company’s ethos of evolution, we aim to increase production and capacity as necessary and march ahead with the conviction of becoming one of the top 10 steel companies in India. To that end, Evonith aims to ramp up production capacity to over 2.5 MTPA by 2025 at the Wardha Steel Complex alone. Evonith aims to do that without compromising on the quality of its steel.

Evonith is also leading the way in India towards sustainable steel production. Through expanding their 1 MTPA capacity Electric Arc Furnace and recycling ferrous scrap, they seek to reduce their carbon footprint while staying on course as one of the top steel producers. Evonith’s goal is a lofty one – to become renowned for not only being a leading steel producer but also being environmentally responsible.

From humble beginnings to here, to growing on to becoming a top steel producer in India, here are the highlights of our steel manufacturing processes.

Highlights

Safety

When it comes to the well-being of our staff and customers, we are uncompromising - zero tolerance for shortcuts when it comes to safety protocol.

EAF Slag

We lower production costs by taking advantage of EAF Slag in the manufacturing process, allowing us to offer high-quality steel at significantly lower costs

Recycled & Sustainable

To be sustainable, we use recycled ferrous scrap to reduce environmental impact without compromising on steel quality.

EAF Tech

Electric Arc Furnace or EAF tech allows for quality steelmaking with unprecedented levels of efficiency and sustainability.

Energy Independent

Drawing on Blast Furnace Gas for its power needs, our Iron Making Complex is now energy self-sufficient. This is our giant leap towards achieving sustainability!

Lower Fossil Fuel Dependency

Coke Oven Gas has replaced traditional fossil fuels like LDO and HSD oils, enabling us to reduce our carbon footprint and go green.

Evonith Metallics Limited (EML)

Consistency and reliability are hallmarks of our ironmaking facility, where the two cutting-edge blast furnaces produce 1.5 MTPA of hot metal – utilised by the in-house steelmaker at EVSL as well as external customers. EML’s capabilities have grown significantly over time, ensuring that no one ever has to go without a steady stream of this essential product.

Email : cs@evonith.com

Registered Office Address:

Office No. 706 to 710, Balarama Building, Bandra Kurla Complex Road, E Block, BKC, Bandra East, Mumbai 400051

CIN: U27200HR2007PLC037927

Evonith Value Steel Limited (EVSL)

Formerly Uttam Value Steels Limited

Our 1.0 MTPA capacity electric-arc furnaces are the unleashing force powering our operations here at EVSL, fusing recycled scrap and hot metal from EML into high-quality flat steel products. Not only does this demonstrate an impressive level of control but also allows us to reduce our carbon footprint – a welcome benefit for all stakeholders.

Email: cs@evonith.com

Registered Office Address:

Office No. 706 to 710, Balarama Building, Bandra Kurla Complex Road, E Block, BKC, Bandra East, Mumbai 400051

CIN: U27100MH1970PLC014621

Disclaimer: Evonith Private Limited, with its registered office in Mumbai, India, is the registered trademark holder of the “Evonith” brand name and “Tripeak” logo. The name, logo and other related marques (Evonith Steel, Neelpankh) will be used under license by Evonith Metallics Limited and Evonith Value Steel Limited.

Corporate Office

- Balarama Building, Bandra Kurla Complex Road, E Block, Bandra East Mumbai 400 051

- TEL : 1800-2689-823

- Email : help@evonith.com

Corporate Office

- Balarama Building, Bandra Kurla Complex Road, E Block, Bandra East Mumbai 400 051

- TEL : 1800-2689-823

- Email : help@evonith.com

It is with immense pride that we unveil Evonith Steel’s inaugural Environmental, Social, and Governance (ESG) Report, a momentous milestone that signifies our unwavering commitment to ESG principles throughout our organization. This report is a comprehensive reflection of our journey, providing invaluable insights into the progress made, results achieved, and our future commitments.

It is with immense pride that we unveil Evonith Steel’s inaugural Environmental, Social, and Governance (ESG) Report, a momentous milestone that signifies our unwavering commitment to ESG principles throughout our organization. This report is a comprehensive reflection of our journey, providing invaluable insights into the progress made, results achieved, and our future commitments.